LUBRICANT PROCESSING AIDS

HK-175A HK-175B

Lubricant processing aids HK-175A and HK-175B are both ultra-low molecular weight copolymer with core-shell structure...

Brief Introduction

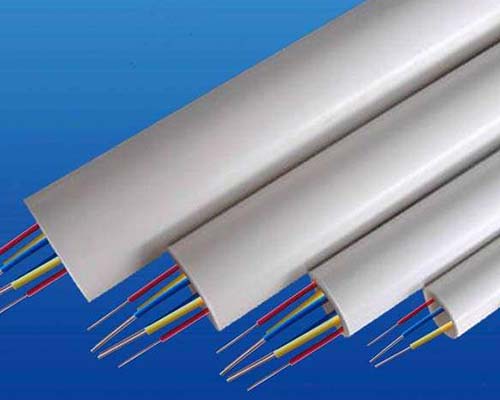

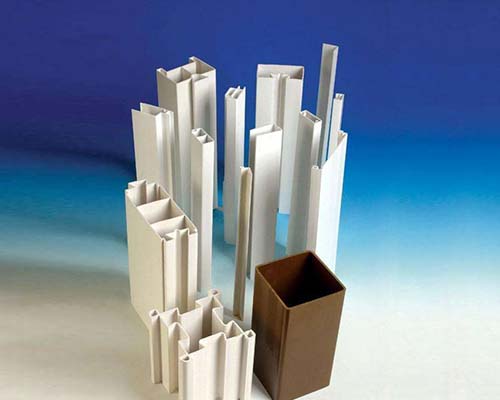

Lubricant processing aids HK-175A and HK-175B are both ultra-low molecular weight copolymer with core-shell structure which are made from special molecular regulators and prepared by seeded emulsion polymerization technology.It can be widely used in all kinds of PVC products. For example, PVC transparent film, plastic sheet, PVC profile, shaped profile, pipe and fitting, PVC foamed board, WPC, building template, injection molding plastic part, etc.

Product Advantage

· Low molecular, quick melting at low temperature and outstanding metal release property.

· Reduce crystal point and flow liner and avoid phenomena of migration.

· Improve the PVC cohesion and uniformity.

· Reduce crystal point and flow liner and avoid phenomena of migration.

· Improve the PVC cohesion and uniformity.

Technical Indicators

| Model | Intrinsic Viscosityη(25°C) | Weight Average Molecular Weight | Molecular Distribution | Density (g/cm2) | Volatile(%) | Residue Sieve (30 mesh %) |

| HK-175A | 0.80-1.50 | (1.000-1.500)×106 | ≤1.150 | 0.45 ± 0.10 | ≤1.3 | ≤2.0 |

| HK-175B | 1.80-2.20 | (3.800-5.000)×106 | ≤1.150 | 0.45 ± 0.10 | ≤1.3 | ≤2.0 |

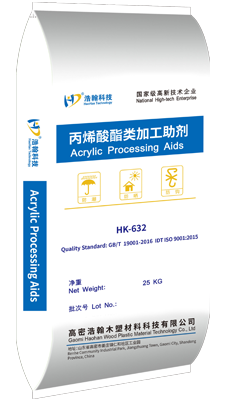

Packaging and Storage

· 25KG/20KG PP Valve Bag with Liner or Kraft Paper Bag.

· 500KG or 1000KG Jumbo Bag; Free-Fumigation Pallet.

· Shelf life: 2 years stored in cool and dry condition.

· 500KG or 1000KG Jumbo Bag; Free-Fumigation Pallet.

· Shelf life: 2 years stored in cool and dry condition.

After-sales Service

Match Product, Optimize Formula, Improve Quality, Increase Production, Reduce Cost.

Get Your Solution

Tell us your needs and we will provide you with customized solutions!